Clothing Construction Theory is the study of the principles, techniques, and processes involved in assembling a garment from raw materials (fabric, notions, etc.) to a finished, wearable product. It provides the systematic knowledge base for the practical skill of sewing and manufacturing.

🏗️ Core Principles of Garment Assembly

The theory emphasizes several key principles that ensure the quality, fit, and durability of a garment:

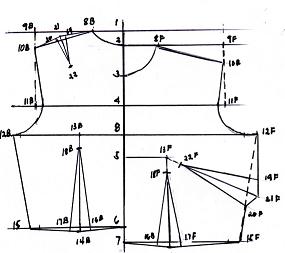

1. Fit and Balance

-

Definition: The relationship of the garment to the body, ensuring it hangs correctly and allows for comfortable movement.

-

Theory: Achieving proper ease (the difference between body measurement and garment measurement), aligning grainlines , and ensuring the garment is on-balance so it doesn't pull, twist, or sag.

-

Key Concept: Darts and Seam Shaping are used to translate the three-dimensional curves of the body onto flat fabric pieces.

2. Sequence of Construction

-

Definition: The prescribed order in which garment sections must be sewn together for efficient and high-quality results.

-

Theory: Construction is almost always approached from the inside out and small components to large components. For example, pockets, collars, and cuffs are fully prepared before being attached to the main body pieces. This ensures accessibility for sewing and finishing.

3. Seam Technology

-

Definition: The methods used to join two or more pieces of fabric.

-

Theory: The selection of a seam type (e.g., plain, French, flat-felled) is based on the fabric type, the garment area (stress points), and the required finish.

-

Plain Seams are the most common.

-

French Seams enclose the raw edges for a neat finish on sheer or lightweight fabrics.

-

Flat-Felled Seams are highly durable and neat (common in jeans and workwear).

-

4. Pressing

-

Definition: Using heat, moisture, and pressure to permanently shape the fabric during construction.

-

Theory: Pressing is considered half of the construction process. "Pressing as you sew" sets stitches, blends seams, and creates smooth curves and sharp edges (like collars and lapels). Pressing should follow the grainline of the fabric to prevent stretching.

✂️ Key Construction Components

Interfacings and Underlinings

-

Interfacing: A layer applied to specific areas (collars, cuffs, waistbands, facings) to provide stability, shape retention, and body .

-

Underlining: A layer of fabric cut to the exact size of the main garment piece and treated as one, used to support delicate fabrics or make lightweight fabrics opaque.

Edge Finishes

-

Facings: Fabric pieces used to finish and support the raw edge of a garment (necklines, armholes), usually turned to the inside.

-

Hems: The method used to finish the bottom edge of a garment, such as turned-and-stitched, rolled, or blind hems.

Closures

-

Theory: Selection and application of functional closures (zippers, buttons, hooks, snaps) must be integrated into the construction sequence correctly and often require reinforcement (e.g., interfacing or backings) to withstand stress.

- Teacher: Admin User